![[LogoShip]](logo5.png)

Software for Windows

Science with your Sound Card!

Features:

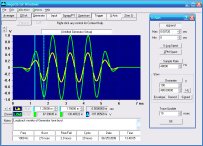

Oscilloscope

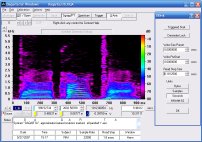

Spectrum Analyzer

8-Channel

Signal Generator

(Absolutely FREE!)

Spectrogram

Pitch Tracker

Pitch-to-MIDI

DaqMusiq Generator

(Free Music... Forever!)

Engine Simulator

LCR Meter

Remote Operation

DC Measurements

True RMS Voltmeter

Sound Level Meter

Frequency Counter

Period

Event

Spectral Event

Temperature

Pressure

MHz Frequencies

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Applications:

Frequency response

Distortion measurement

Speech and music

Microphone calibration

Loudspeaker test

Auditory phenomena

Musical instrument tuning

Animal sound

Evoked potentials

Rotating machinery

Automotive

Product test

Contact us about

your application!

Board Preparation

After drilling from the top side, the holes on the metal side of the board will now have rough edges from the dental burr piercing through. You must sand these smooth to the touch, without scratching up the rest of the copper surface. The best way to do this is by wet-sanding with a small piece of "Wet-or-Dry" sandpaper, 400 grit or so. (This is the black or dark gray paper.) Rinse frequently while you are sanding. The same scrap of paper can be used repeatedly for many boards.

Next, the copper surface must be scoured clean to remove any oils or oxidation that didn't come off in the sanding. Use a regular kitchen-type steel wool / soap pad like "Brillo" or "SOS" for this, then wash the board with a drop of dish detergent and rinse thoroughly to remove traces of soap and steel fibers. You may want to try other scouring pads like "Scotch-Brite", etc, which can be used directly with dish detergent.

Alternatively, you can use a small tuft of very fine (grade 00 or finer) steel wool with a drop of dish detergent. Again, make sure you rinse off all stray steel fibers as well as the detergent.

Dry with a clean towel... the copper should have a soft shine. Avoid touching the surface.

See also Printed Circuit Construction

- Back to Marking and Drilling

- Ahead to Drawing Resist Lines

- Daqarta Help Contents

- Daqarta Help Index

- Daqarta Downloads

- Daqarta Home Page

- Purchase Daqarta

Questions? Comments? Contact us!

We respond to ALL inquiries, typically within 24 hrs.INTERSTELLAR RESEARCH:

Over 35 Years of Innovative Instrumentation

© Copyright 2007 - 2023 by Interstellar Research

All rights reserved