![[LogoShip]](logo5.png)

Software for Windows

Science with your Sound Card!

Sound Card - Engine Crank and Cam Sensor Simulator

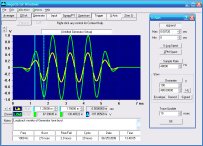

The above image shows the Daqarta Generator running the Engine_Sim Engine Crank and Cam Sensor Simulator Mini-App that is included with Daqarta. (Note that this remains fully functional after the Daqarta trial period... it's completely free.)

The mini-app simulates the output from an engine's crank (solid green) and cam (violet) position sensors, for testing an Electronic Control Unit (ECU) or Module (ECM) without an engine present.

Engine_Sim can simulate systems with Variable Valve Timing (VVT), as shown in the image above. It shows a crank output and two cam outputs, with the Intake cam sensor at 40 degrees (violet) and Exhaust cam sensor at 25 degrees (dashed green) relative to the base crank reference. You can adjust these independently while the simulated engine is running.

Engine_Sim also supports another 3-sensor engine type called CYP that replaces the single cam sensor with separate TDC and CYL sensors.

For either of these 3-sensor designs you'll need a sound card with multi-channel outputs. The inexpensive (about US $25) 5.1 Channel CM6206 USB device discussed in Sound Card Performance Tests is a good choice for this purpose.

However, even a standard stereo card can simulate all 3 outputs for display purposes, as in the dashed green Exhaust cam shown above.

The above image shows SIMULATION Mode running. When Engine_Sim starts it is in DESIGN Mode, with controls for setting basic engine parameters like base number of teeth (36 crank teeth here) and number of missing or extra teeth to indicate the reference tooth (slightly taller, marked by vertical blue cursor line). You can optionally load a Custom Profile with arbitrary tooth widths and positions that you specify. For the cam in the above design this was a file called VVT2.TXT.

When you have the design ready, the Create Arb button saves it for later simulations. You can create a library of saved designs; you don't have to go through the design process each time you simulate.

During simulation, the default mode is Constant RPM, whose speed defaults to 1000 RPM but can be easily changed with the Set Constant RPM control; here it has been set to 2000 RPM.

Toggling the Constant RPM simulation mode advances to 600-6000 RPM Sine Cycle, and Set Constant RPM becomes RPM Test Cycle with a default of 10 sec. This mode smoothly cycles the simulated engine speed back and forth between 600 and 6000 RPM (or whatever limits you specify), with a period set by the RPM Test Cycle control. The instantaneous speed is always shown via the RPM mode readout on the Frequency Counter at the bottom of the image, here showing a constant 2000 RPM.

The Sine Cycle can be toggled to Arbitrary Schedule Cycle to run your own RPM test schedule. A default schedule is included that ramps from 600 RPM to 3000, holds, ramps to 6000, holds, and returns to 600 RPM over the RPM Test Cycle interval.

You can easily create your own RPM schedule using the included Arb_From_List mini-app. You just give it a list of times and RPMs and it does the rest, including displaying RPM versus time so you can verify that it's what you intended. The schedule used for the default is:

;sec RPM

0.00 600

2.00 3000

4.00 3000

5.00 6000

6.00 6000

8.00 600

10.00 600

The simulation uses a trick to allow the trace to synchronize to the crank or cam reference: The reference tooth (first pulse after the gap) is automatically made slightly taller than the rest, and the display Trigger Level is set to catch this pulse but miss the rest. (The violet Intake cam reference pulse is likewise taller, but that's not obvious here because there is no adjacent cam pulse on the screen for comparison.)

Without this trick, each trace update would sync to whatever pulse from the stream happened to arrive next, and the reference gap would roll arbitrarily across the trace. (The ECU wouldn't care, but it would be hard on the eyes. The Frequency Counter could still read the correct RPM, since Engine_Sim tells it how many crank or cam pulses are in one engine revolution via a fake number of Cylinders setting.

See the External Connections subtopic under Engine Crank and Cam Sensor Simulator Mini-App for a discussion of how to connect your sound card outputs to an actual ECM/ECU.

Features:

Oscilloscope

Spectrum Analyzer

8-Channel

Signal Generator

(Absolutely FREE!)

Spectrogram

Pitch Tracker

Pitch-to-MIDI

DaqMusiq Generator

(Free Music... Forever!)

Engine Simulator

LCR Meter

Remote Operation

DC Measurements

True RMS Voltmeter

Sound Level Meter

Frequency Counter

Period

Event

Spectral Event

Temperature

Pressure

MHz Frequencies

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Applications:

Frequency response

Distortion measurement

Speech and music

Microphone calibration

Loudspeaker test

Auditory phenomena

Musical instrument tuning

Animal sound

Evoked potentials

Rotating machinery

Automotive

Product test

Contact us about

your application!

Questions? Comments? Contact us!

We respond to ALL inquiries, typically within 24 hrs.INTERSTELLAR RESEARCH:

Over 35 Years of Innovative Instrumentation

© Copyright 2007 - 2023 by Interstellar Research

All rights reserved