![[LogoShip]](logo5.png)

Software for Windows

Science with your Sound Card!

Features:

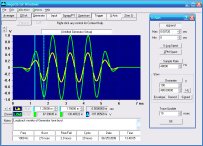

Oscilloscope

Spectrum Analyzer

8-Channel

Signal Generator

(Absolutely FREE!)

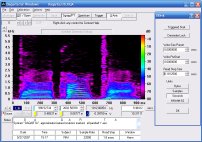

Spectrogram

Pitch Tracker

Pitch-to-MIDI

DaqMusiq Generator

(Free Music... Forever!)

Engine Simulator

LCR Meter

Remote Operation

DC Measurements

True RMS Voltmeter

Sound Level Meter

Frequency Counter

Period

Event

Spectral Event

Temperature

Pressure

MHz Frequencies

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Data Logger

Waveform Averager

Histogram

Post-Stimulus Time

Histogram (PSTH)

THD Meter

IMD Meter

Precision Phase Meter

Pulse Meter

Macro System

Multi-Trace Arrays

Trigger Controls

Auto-Calibration

Spectral Peak Track

Spectrum Limit Testing

Direct-to-Disk Recording

Accessibility

Applications:

Frequency response

Distortion measurement

Speech and music

Microphone calibration

Loudspeaker test

Auditory phenomena

Musical instrument tuning

Animal sound

Evoked potentials

Rotating machinery

Automotive

Product test

Contact us about

your application!

Introduction to the Direct-Draw Method

Printed circuits are made from thin, rigid boards with copper foil laminated onto them. The "wires" of the desired circuit are created by creating lines on the copper foil using a "resist" medium, then the unwanted foil is removed using an etchant solution that dissolves the unprotected copper. Holes are drilled for the electronic component leads, and the boards are "stuffed" with components and soldered.

In commercial production, the raw copper-clad boards are coated with a photo-resist, and the conductor lines are created by exposing the photo-resist to UV light through a negative mask. UV light hitting the photo-resist causes it to harden, after which the remainder of the resist is washed away with solvents to leave only the resist-covered lines on the copper, ready for etching.

For low-volume home and small lab use, there are simpler ways to get the resist lines onto the copper. One popular method, discussed on many Websites, involves the use of a laser printer to print the desired circuit pattern onto a transfer medium. This may be a special transfer film, or ink-jet photo paper, or stick-on label backing paper, or even glossy (clay-coated) advertising or magazine paper. The printed image is then placed face-down onto the copper-clad board and a household iron is used to fuse the plastic toner to the copper. The paper is then removed by soaking and scrubbing, leaving a ready-to-etch board. After etching, the toner is removed with solvent to prepare for soldering.

Note: The laser printer iron-on method uses the left board layout, marked "TOP (X-RAY) VIEW". This will give the correct result when the printed image is ironed onto the bottom (foil) side of the board.)

There are a number of process details that must be dealt with to use the laser toner transfer method, including finding the right paper or transfer medium, and getting the proper ironing technique. If you need to make many boards, however, it is worth the investment of time (and materials, if you have to find the right brand of paper), since complex, high-quality boards can be made with this method.

On the other hand, if you haven't made circuit boards before, and only need to make a few small circuits, the direct-draw method described here may prove to be simpler. You'll still need some supplies like copper-clad board, etchant, and a small high-speed hand tool like a Dremel for drilling, which you would need with either method. But you won't need any nasty solvents, and you won't even need access to a laser printer. (An ink-jet will work for the direct-draw method.)

The basic idea is that you draw the desired pattern by hand onto the copper surface, using an indelible felt-tip marker to provide the resist. With this method, you use the printed layout to mark and drill the holes first. Then the drawing is simply a matter of "connecting the dots" using the printed layout as a guide. For the simple cicuits included with Daqarta, the drawing only takes a few minutes.

This direct-draw method has been extensively tested and refined, and has been used to create hundreds of boards for hobby, business, and university research use.

If you are using the Daqarta layouts, or perhaps those of your own that you have created with a CAD (Computer Aided Design) program like ExpressPCB and printed out, skip ahead to Board Selection.

If you want to create your own simple layouts without a CAD program, continue to Circuit Layout.

If you are using the laser toner transfer method, you should still read Board Selection, Board Preparation, and especially Etching and Marking and Drilling.

With the laser toner method you drill the holes after etching, and you don't usually have to mark them since the layout will include small holes in the copper pads that serve as guides for drilling. Also, you will be drilling from the copper side to the bare side, so there will be no deburring needed.

See also Printed Circuit Construction

- Back to Printed Circuit Construction

- Ahead to Circuit Layout

- Daqarta Help Contents

- Daqarta Help Index

- Daqarta Downloads

- Daqarta Home Page

- Purchase Daqarta

Questions? Comments? Contact us!

We respond to ALL inquiries, typically within 24 hrs.INTERSTELLAR RESEARCH:

Over 35 Years of Innovative Instrumentation

© Copyright 2007 - 2023 by Interstellar Research

All rights reserved